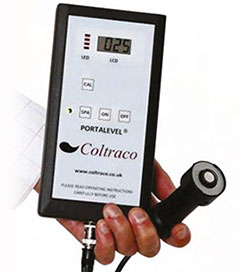

Ultrasonic Liquid Level Indicator

Copyright 2019 Australian Fire Enterprises ABN 72 079 715 067 | Privacy Policy | Contact Us

Technology:

The Portalevel® Standard uses ultrasonic technology to identify the interface between liquid and air in any single skinned container. It therefore has none of the user problems associated with radioactive liquid level indicators which require dedicated training, storage, Health & Safety documentation, and transportation. It also replaces the traditional means of verifying liquid levels by dismantling and weighing in which the system may be closed down or disconnected, risking potential damage in so doing and involving considerable time, expense and inconvenience.

What Does 7th Generation Mean ?

We have upgraded the electronics to enable more intuitive handling and ease of operation, in terms of calibration to a cylinder and the lights and digital display. We have also made an easy-use membrane control and an easy clean fascia panel.

Operation:

The unit is simple to operate using push button controls and requires little training. It is calibrated to each cylinder at the touch of a button. The ultrasonic “dry” sensor requires no water or gel to ensure good transmission

of the ultrasonic signal; the optional “wet” sensor to be used with ultrasonic gel, is suitable for use on poor condition cylinders where thick or irregular coatings or badly pitted and rusty surfaces prevent the dry sensor from obtaining a clear signal. The sensors are housed in a magnetic applicator which ensures good contact with the surface and allows hands-free operation.

To locate the liquid level in a vessel, the sensor applicator is placed on the test vessel below the expected liquid level and then calibrated and all LED lights are lit on the digital unit, or the meter fully deflected on the analogue. The sensor is then placed above the expected level – all lights extinguish. The sensor is moved between these two points in small steps until the interface is located.

For all types of bottles/cylinders, any that are found with unusual readings should be double-checked and if the same readings result, we recommend that the bottle be isolated and removed for weighing to double check its content.

Applications:

The Portalevel® Standard is a versatile instrument that can locate the level of any liquid in any single skinned container of wall thickness 2 – 15 mm. Wall thickness of 15 mm – 90 mm is also possible, depending on material type and vessel size. It cannot monitor contents of plastic

vessels as they do not conduct ultrasound.

It is typically used for high pressure CO2 or Halon cylinders constructed of seamless spun steel, approx 5 ft high, 10 ins diameter, 45 kg or pressed steel with welded seams with low pressure fills of varying sizes and fill weights:

7th Generation Portable Ultrasonic Liquid Level Indicator for CO2, Halon, FM200™, NAF S III, FE 13, CEA 410 & Novec 1230 gaseous extinguishing systems.

Certifications and Approvals:

• Manufactured to BS EN 5750, ISO 9001

• Quality Standard

• RINA Approved

• Manufactured to US MIL-STD

• NATO Stock Number 6680-99-192-2735

• Coltraco Part Number 2290334

• Det Norske Veritas Accepted

• “Portalevel” Trade Mark Registered No 2290334

• UK Government Cage Code KD983

• US Department of Defense Halon

• Depletion Agency approval

a. Fire Extinguishant Cylinders – its primary application is to check levels of liquid gaseous extinguishants in fire cylinders where it can be used to locate levels of CO2, Halon and Halon substitutes such as FM200® and NAF S III. It was recently selected after

stringent comparative testing by the US Department of Defence Halon Depletion Agency for purchase who verified its accuracy to +/- 1.5 mm. We supply many units to fire service companies, offshore installations and utility companies worldwide for this purpose.

b. Marine Multi Banked Cylinders – Using the multi-bank cylinder rod, the Portalevel Standard ® can also verify levels of extinguishants in multi-banked cylinder rows using this extension rod to reach the second and third rows. This type of installation is typically found on board ships and we have extensive experience

of supplying this equipment to the marine sector.

c. LPG – Propane and Butane may be tested though the unit will function in reverse (see e below).

d. Sprinkler Systems - The Portalevel® Standard is a useful tool to check the system integrity of sprinkler systems. The majority of sprinkler systems contain “clean agents” such as CO2, Halon and Halon substitutes for which the Portalevel® was designed

and which few other instruments are able to locate.

e. Water – The Portalevel® can be used to locate water levels but in this case the signal gives inverse readings, ie high readings below level and low readings above.

More Information - Downloads

Portalevel Standard